Achieve staff sufficiency, reduce downtime, and enhance efficiency with our Maintenance Staff Planner and Capacity Planner. Embrace success with meticulous organization, analysis, and planning.

This tool is designed for any business that does any type of scheduled maintenance.

Already have a maintenance system? If so, there is a good chance the utility capability provided by our planning worksheet will still be of use. Your existing system may not support a view of your resources and tasks with endless what-if scenarios that our tool provides.

If you have a maintenance system where all information is entered manually (a paper system), then this tool will work for you as well. This planning worksheet is all about the task. How often you perform the task and the total budgeted time to perform the task. We just know you will get to see your scheduled work from a different perspective by using our worksheet tool.

The implementation of a successful maintenance program requires that the supervisor pay close attention to the preparatory steps. What are these steps? Successful implementation requires a plan for organizing the staff, identifying and prioritizing the equipment based on needs, documenting and estimating the time required to complete each task, and most importantly, establishing the frequency for how often the tasks are to be performed.

For those not possessing Microsoft Office or Microsoft Excel, both LibreOffice and Apache OpenOffice are excellent alternatives that are readily downloadable.

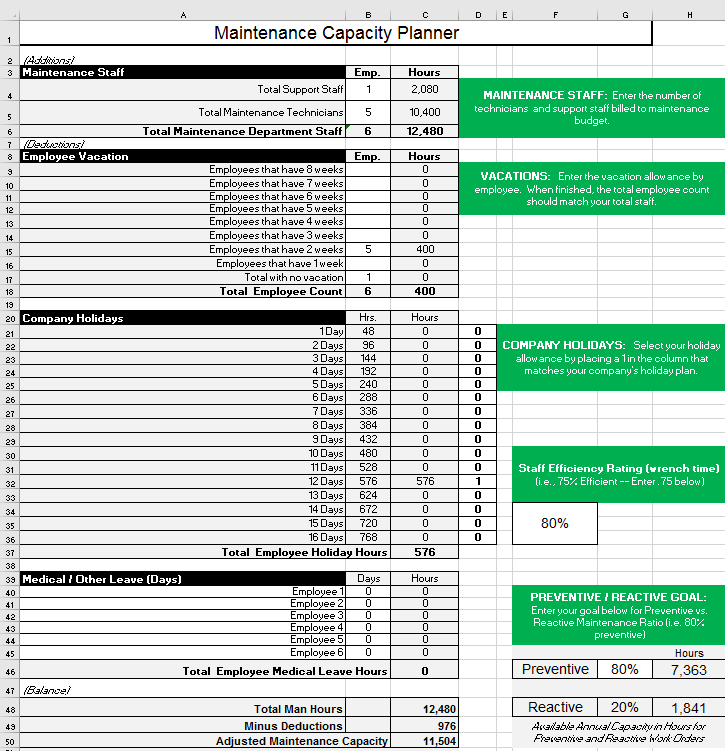

Analyze your resources (ie: employees, vacation, holiday, sick leave, etc.) to ensure you have sufficient man-hours for your annual corrective and preventive maintenance.

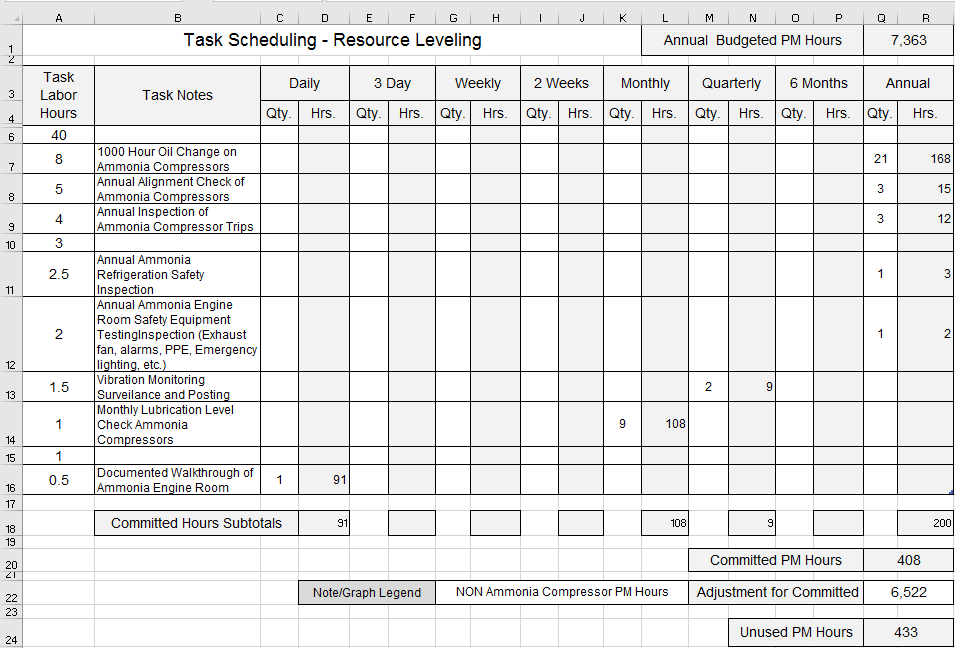

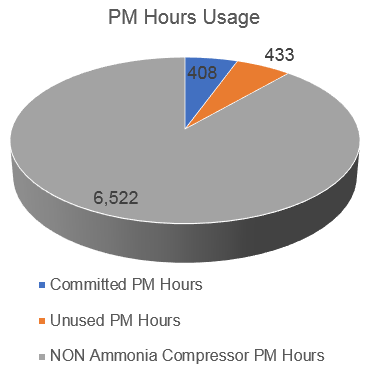

Focus on a system, asset type, or task category within your organization to improve efficiency and ensure that preventive maintenance intervals are performed as required but not too often.

Benefits

How many tasks and how many times per year?

Target critical systems first and level resources.

Example

ABC Food Processing Management recognizes their ammonia refrigeration system is a critical resource and asks the maintenance supervisor to evaluate the scheduling efficiency of preventive maintenance within the system and also how it relates to the overall preventive maintenance budget.

continuing our example... Maintenance Supervisor, Bob Jordan, performs the following steps to target pm task scheduling efficiency on their ammonia system:

CMMS - Mechanic's Mate Maintenance Management System Software

Guides to Improving Maintenance EfficiencyHVAC Published Articles & White Papers

12 Best Practices of Inventory Optimization

What Hides Behind the Term: Lean Maintenance

Operations & Maintenance Best Practices - A Guide to Achieving Operational Efficiency

Guides to CMMSROI Calculator - Justifying the Cost of CMMS

The Business Case - Benefits of a CMMS